1. The Challenge: Complexity at Scale

Manufacturing a single showerhead involves navigating extreme technical hurdles:

- Massive Hole Counts: Between 5,000 to 10,600 holes per part.

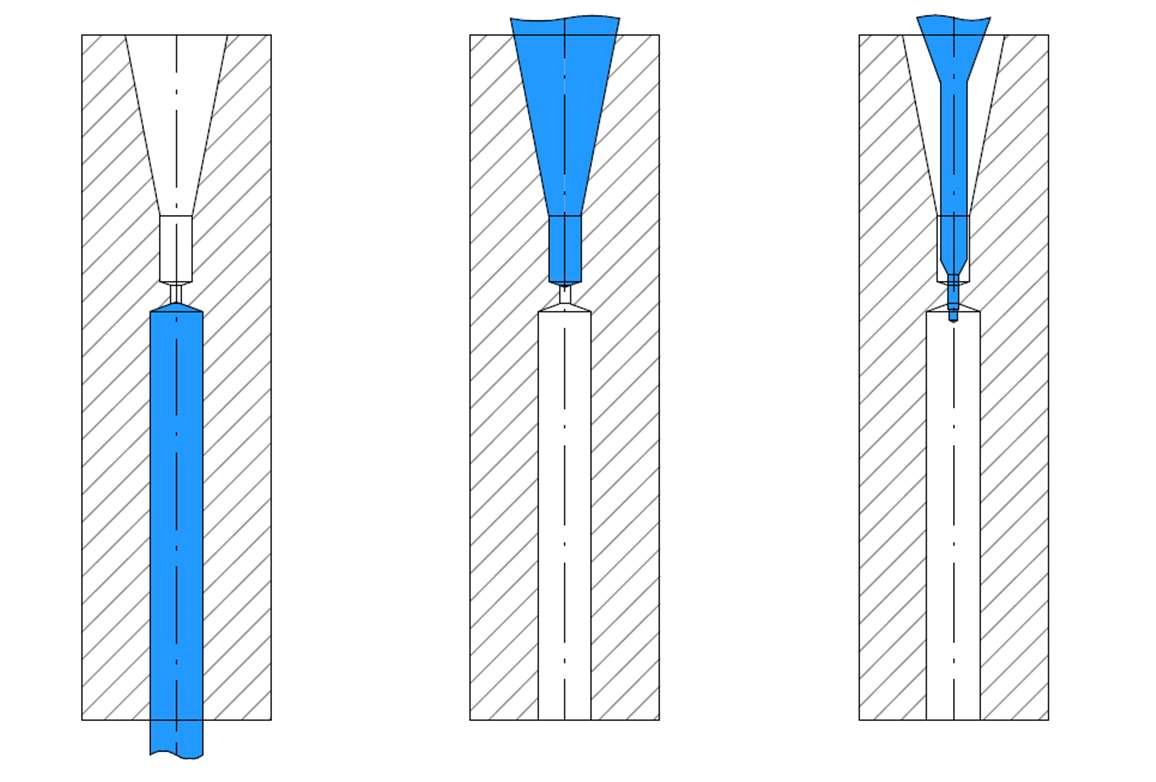

- Diverse Geometries: A mix of single holes, step holes, and “cone + micro-hole” configurations.

- Tight Tolerances: Requirements for surface roughness of and zero-defect exit burrs.

- High Risk: Micro-drilling ( to ) often leads to tool breakage during the exit stage in conventional setups.

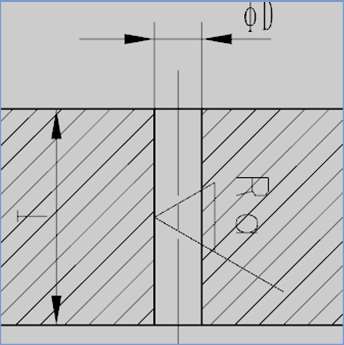

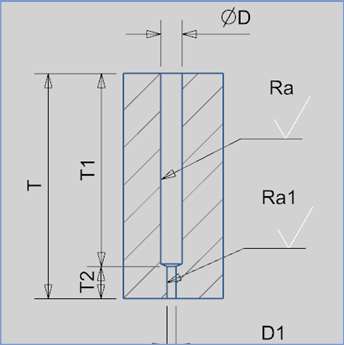

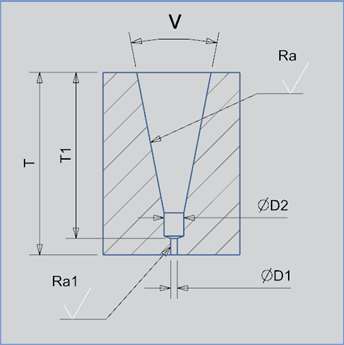

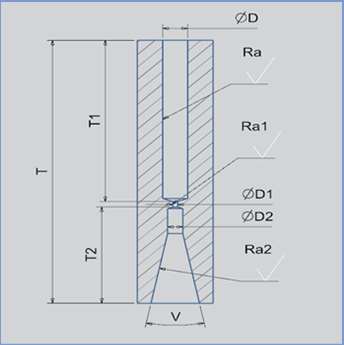

Showerhead Hole Types and Control Points

2. Traditional vs. Mikron Tool Solutions

Manufacturing a single showerhead involves navigating extreme technical hurdles:

- Massive Hole Counts: Between 5,000 to 10,600 holes per part.

- Diverse Geometries: A mix of single holes, step holes, and “cone + micro-hole” configurations.

- Tight Tolerances: Requirements for surface roughness of and zero-defect exit burrs.

- High Risk: Micro-drilling ( to ) often leads to tool breakage during the exit stage in conventional setups.

| Feature | Conventional Method (Competitors) | Mikron Tool Solution |

|---|---|---|

| Tool Variety | Requires 7–8 different tools per hole. | Integrated Special Tools (e.g., Taper Drill + Reamer). |

| Machining Speed | Low feed rates (Vf = 400mm). | High-speed performance (Up to Vf = 720mm). |

| Efficiency | Frequent pecking (every 0.2mm). | No Pecking required; single-pass machining. |

| Throughput | High lead times due to tool changes. | 10,600 holes in just 2 hours. |

3. Specialized Technical Solutions

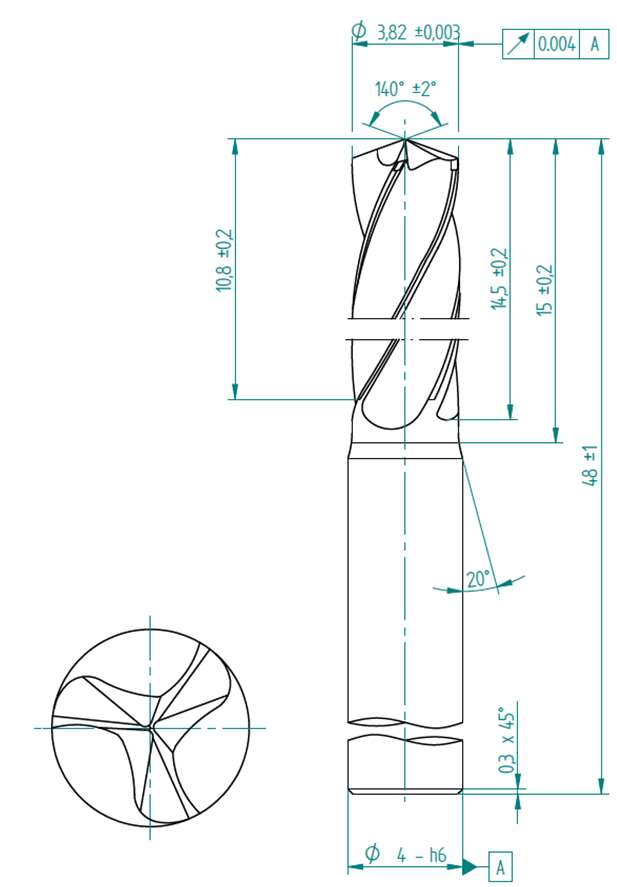

Precision General Drilling

Drill with 3cutting edge drill Drilling:

Utilizing a specialized 3-edge drill, Mikron Tool achieves rapid bulk drilling of over 10,000 holes with N=6500 and Vf=700, maintaining the required Ra < 0.8 without periodic tool retraction.

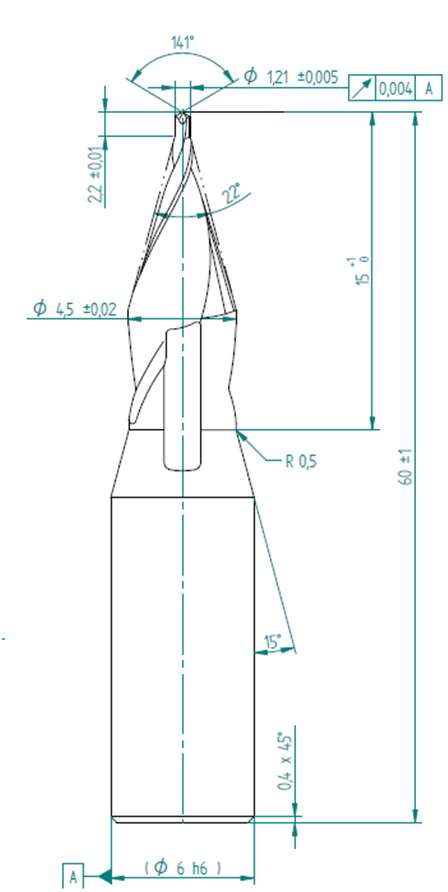

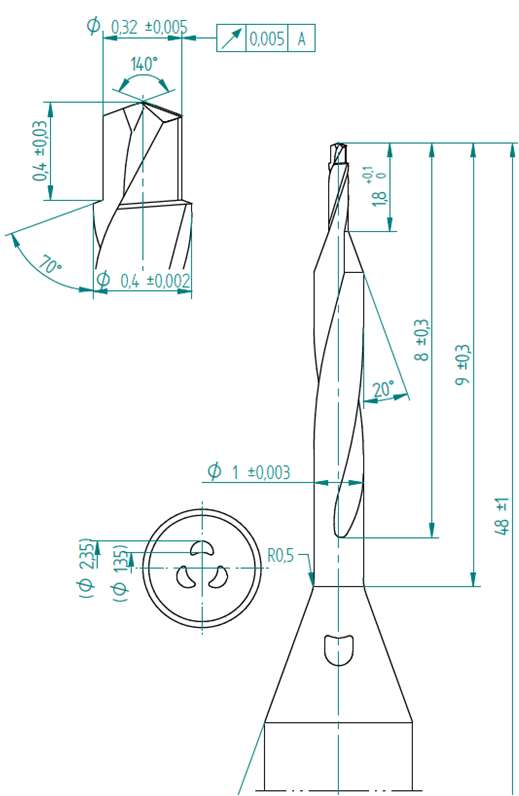

The “Cone + Hole” Integrated Process

Taper Drill&Reamer:

By combining the taper drill and reamer into a single custom tool, Mikron Tool ensures perfect cone roughness and dimensional accuracy in a single operation (N=12000, Vf=500mm).

Micro-Hole & Burr Control

Achieved roughness, tolerance and burr requirements for tested options, no pecking, ensuring stability (N=18,000 Vf=720mm)

4. Key Benefits for Manufacturers

Production Maximization: Radical reduction in cycle times through high-speed parameters.

Superior Quality: Minimized burrs significantly reduce the time needed for post-processing (polishing/lapping).

Process Stability: Lower cutting resistance and specialized bending moment designs extend tool life.

Cost Efficiency: Lower total manufacturing costs through reduced lead times and longer tool replacement cycles.